Chilomoni, Blantyre

The Cycle of Good (COG Malawi) was one of Beehive’s key enterprises and was led by local women. It worked with recycled materials, such as bike inner tubes, coffee sacks and lorry curtaining, to make items to sell in the UK and international markets. 33 women were employed at COG Malawi, all of whom have achieved a Diploma in Tailoring from Beehive’s Tailoring School. COG was housed with Beetech on the main campus.

“The women enjoy working here; they didn’t just want work, they

wanted equality and a say in their work, they get that here.” (Mary Kamwendo, Manager of COG)

“Our culture is to work hard to support the whole extended family and that’s what working here means to the tailors. They can pay school fees for children, buy food and clothes.”

(Mary Kamwendo, Manager of COG)

The Cycle of Good helped empower local women and jobs were highly sought after. All tailors qualify from Beehive’s Tailoring school, and COG offered an alternative career path to the traditional khonde tailor role, (informal work typically done from home). This is vitally important, as many khonde tailors are struggling to maintain sustainable businesses with the increasing number of cheap, second-hand clothing coming into the country. COG was established in 2015, and in a short space of time had built a financially stable business, with a portfolio of high quality products and a strong client base of over 200 UK stores. It will enable COG to further support the most vulnerable in society, as all surplus profits go into funding the community outreach work at Mother Teresa Outreach Centre. The ladies formed a tight knit team and have chosen to have a combined bonus scheme where they all have to meet their production and quality targets for anyone to get a bonus. This has created a supportive environment, where the team cheer on each others successes. The sustainable principles that underpin COG of utilising unwanted items that will otherwise go into landfill, has also helped educate people on the importance of minimising waste in the fight against climate change.

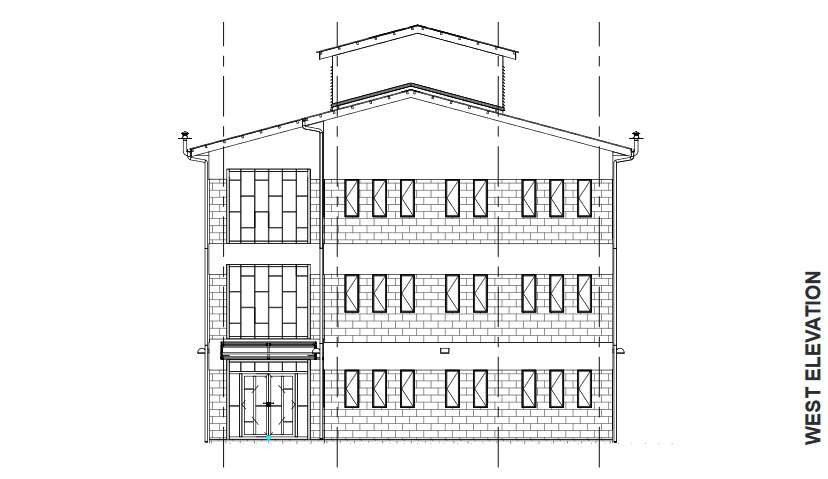

Building Design

Location

Type

Year of Construction

2017 – 2018

Design Architect

Donn Ponnighaus

Project Architects

Donn Ponnighaus and Keith Banda

Design Engineer

Zedi Nyirenda

Geotechnical Engineer

Zedi Nyirenda

Project Engineer

Hendrix Mgawana

Total Building Area (Approx. GEA)

673m²

Number of Storeys

3

Construction Cost

256,859,000 MWK

(£260,834 GBP – rate correct as of 25th August 2020)

Cost per m²

381,663 MWK/m²

(£388 GBP/m²)

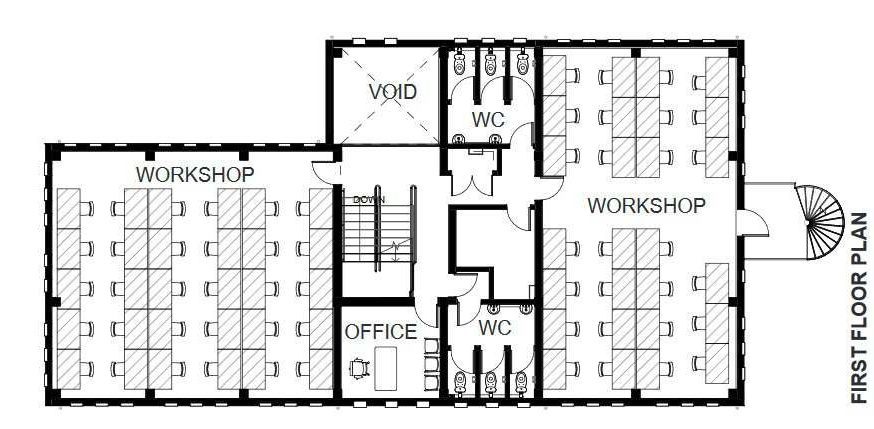

The BeeTech building was designed around three floors of large, open plan workshops, with smaller rentable units on the ground floor that are open to the general public. The grid allows for two workshops per floor, which can be subdivided into 4 smaller units, creating a flexible floor plan that helps to future proof the building. The plan has three key zones, with the workshops sitting to the south and an open air, covered walkway to the north. In between sits a service zone for small meetings rooms, storage and washrooms, providing easy access from both workshops and circulation.

All spaces are naturally lit and ventilated with views out to the surrounding landscape, creating a comfortable environment to work in. They

will be powered by the sun and the roof has been designed to accommodate solar panels on its north face, with level access for maintenance provided from the flat roof over the external walkway. The building is designed as a concrete structural frame, with an infill of Beehive’s hydraform, earth blocks. It is located at one of the primary entrances into the Technology and Enterprise Park, and the concrete frame has been extended into the public realm to create a welcoming arrival to the campus. It also helps to encourage the general public into the site, so they can access the rentable units at the ground floor of the building.

Meet The Team

Yamikani M. Chandiyang'ana

Tailor (COG)

Matilda Jalasi

Tailor (COG)

My name is Ida M’dalangwa Baluti. I have been working at Beehive in the Cycle of Good department, as a tailor, from the 1st July 2017. My role is to sew different recycled products from inner tubes and sacks. My favourite thing about my work is sewing with the team – with smiles and laughter work is made easy.

Ida M'dalangwa Baluti

Tailor (COG)

The project contributed to the following Sustainable Development Goals